Once the stock flywheel diameter was determined to be OK, some weight still needed to come off them. I chose to shave them to my own version of the S&S Knife Edge modification. When you have one spinning in the lathe, as shown below, the weight comes off pretty quick.

Below is the un-modified flywheel on left, and the lightened on the right. You need to be careful not to remove too much weight from the side opposite the rods, lest you don't leave enough to bring them into balance. This is particularly important to take into consideration when dealing with heavy, big bore pistons.

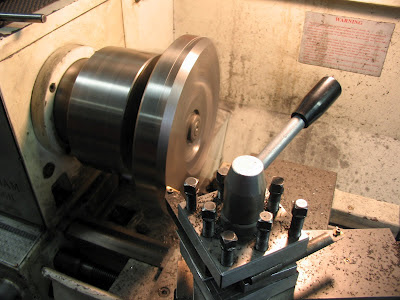

Before balancing, one needs to get the pistons to their final weight. In this case, that meant the combustion chambers needed to be finished so that the compression ratio could be established in case material needed to come off the top of the piston to lower it. Below, one of the heads is mounted in the lathe to machine a firering recess for the Axtell cylinders, as well as the 30 degree chamber to match the pistons.

One of the first steps on this engine build was to weld up the floor of the intake ports. While I was at it, I added some aluminum to the sides of the combustion chamber since I was not sure what it would take to get to my target compression ratio of 16:1. The nearly finished chamber as shown below came out to 20:1 after calculating it with the domed piston. Guess I wouldn't have had to add that material to the chamber!

The domes on these 30 degree pistons are solid, which leaves plenty of room for modification. Milling .300" off the top of the dome, as shown below, brought the compression down close to the target. The piston on the right has been machined. More material will be taken out on the under side of the domes to lighten before balancing.

More to come ...

1 comment:

Hi Lee, I was thinking you were going to change the chambers like that, looks great so far.

Mark.

Post a Comment